|

Characterization

of the spatial resolution of the microscope is

an important and active project in our group.

Here, we use the following definition of resolution:

Res

= half-period of a equal line and space pattern

that exhibits Rayleigh-like 26.5% modulation in

its image

The

resolution, in general, can be expressed as  . .

is the radiation wavelength, and NA is the numerical

aperture of the imaging optic.

is the radiation wavelength, and NA is the numerical

aperture of the imaging optic.  is a constant which primarily depends on the degree

of partial coherence of the illumination,

is a constant which primarily depends on the degree

of partial coherence of the illumination,  .

In our case, NA is equal to .

In our case, NA is equal to  ,

where ,

where  is the outermost zone width of the micro zone

plate. Thus,

is the outermost zone width of the micro zone

plate. Thus,

Res

=

The

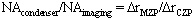

degree of partial coherence of the microscope,

,

is equal to ,

is equal to . .

is the outermost zone width of the condenser zone

plate (CZP). Typically,

is the outermost zone width of the condenser zone

plate (CZP). Typically,  is from 0.4 to 0.7, and

is from 0.4 to 0.7, and  from 0.6 to 0.8. The resolution of the full-field

microscope is slightly finer than the smallest

zone width of the micro zone plate.

from 0.6 to 0.8. The resolution of the full-field

microscope is slightly finer than the smallest

zone width of the micro zone plate.

We design and fabricate various test objects for

measurement of the microscope’s resolution.

Test objects and measurement result are discussed

below.

|